Manufacturing is an industry that is constantly looking for ways to operate leaner and more efficiently. From production to shipping, from supply chain management to employee attraction and retention, manufacturers are always in motion and required to meet often-tight deadlines on an ongoing basis. So finding ways to save money while doing this becomes critical.

One way in which some manufacturers have found success in this area and others certainly could as well, is through business practice outsourcing (BPO) in certain areas, or simply externalizing certain company functions. While this model is likely not the solution for manufacturers for their core operations such as the production floor or research and development, it absolutely can work with back-office functions, such as payroll, human resources, and accounting.

By repositioning these areas with BPO, the day-to-day operations of the manufacturing company can be better managed. Outsourcing these types of financial or HR services can actually go a long way toward helping manufacturers focus on their goals, bring more efficiencies to the overall operation, and reduce overhead costs.

BPO can alleviate workload and time-consuming tasks for various departments that eat into the company’s bottom line. By employing BPO in tasks such as bookkeeping, tax return processing, auditing, and year-end financial reporting, it’s one more burden taken off of the manufacturer and allows for better concentration on what the business does best—developing, producing, and shipping products to its customers.

Manufacturers best poised to take advantage of BPO are those either in the start-up phase of operation or those who function as suppliers for larger companies. In the case of the former, with a fledgling manufacturing business, why devote resources at the outset to creating internal finance and HR departments, when they can be better used to getting the operation off the ground. With suppliers, many of whom are small machine or production shops, it’s a similar benefit—the expense of outsourcing these departments can be far less than creating them in-house. The bottom line in both is efficiency—a startup or supplier likely has a great idea or a great product to offer, and that is where their expertise lies and their energy should be.

And that remains perhaps the most essential benefit of bringing BPO into a manufacturing business—keeping the focus on the businesses’ core competencies and doing what it does best. BPO helps to keep strategic priorities front and center while leaving the back office tasks to professionals who do that for a living—it will both save money and bring peace of mind that the operation is sound. The alternative is nowhere near as attractive—a manufacturing business that overextends itself into areas less known to it has a much greater chance of losing core focus and damaging both productivity and customer relations. No one wants that to happen, which is why BPO services make sense for manufacturing companies.

In a time of increased competition and a global market where margins are often razor-thin, manufacturers are looking for every way possible to save money and invest in their company right away. Exploring BPO for back-office operations is one proven way to keep things moving in the right direction.

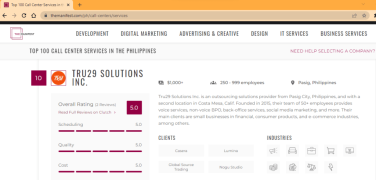

Tru29 has a robust understanding of the changing face of back-office services. Through a partnership with us, you can be assured that you will be adding value to your business today while taking the first steps towards ensuring preparedness for tomorrow.